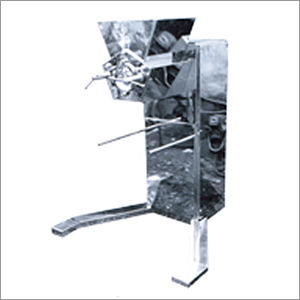

Rapid Mixer Granulator

Product Details:

Product Description

Backed by a team of dexterous professionals, we are engaged in manufacturing, supplying and exporting premium quality Rapid Mixer Granulator. These granulators are appreciated for providing higher productivity, lowering operating cost, excellent mixing, least rejections, improved quality and faster tableting speeds. Offered product is highly demanded around the globe, owing to their features and thus we manufacture these products at very large scale to meet the high demands. Valued customers can avail Rapid Mixer Granulator from us at most affordable prices.

Salient Features

-

All contact parts are made out of S.S.316 as per GMP standard.

-

Three blade Design for efficient mixing with a high speed granulator (chopper) is inserted horizontally through the wall of the bowl to assist blending of powder and to break the product to granules of required size.

-

Platform is SS 304 which is dimpled for anti slip property entire stand is also cladded by SS 304 to make the machine total GMP.

-

Chopper housing is entirely made from SS 304 having air purging and special seals. Discharge piston has face sealing matching the vessel interior.

-

Two stage housing for main impeller eliminating totally any chance of cross contamination between bearing grease and product mix.

-

Lifter can be fitted for loading of material.

-

5 microns filter assembly will be provided on top lid in stainless steel housing to eliminate dusting in granulation area.

-

All Electrial & pneumatic parts are pre wired to simplify installation.

-

Discharge can be provided on either side to suit clients requirement.

Optional Accessories / Attachments

-

PLC with touch screen MMI with printing facility

-

VFD can be provided to change the RPM of impeller

-

WIP system

-

Flame proof Construction

-

Online co-mill arrangement

-

Steam jacketed Bowl

-

Blinder charging with dosing pump

-

Emergency push button station at discharge

-

Granulation end point detection.

Safety

-

Proximity switches are provided on main lid and discharge valve interlocked with central control system for safe operation.

-

Equipment air and purging air control via differential air switches.

-

Location of the FBD bowl at discharge i.e. FBD bowl touch the proximity sensor then discharge will open.

STANDARD PROCESSING DURATION

Dry mixing : 3 to 5 minutes

Wet mixing : 5 to 10 minutes

Wet granulation : 5 to 10 minutes

Discharge : 1 to 1.5 minutes